Office Add: Zhengzhou City, Henan, China

E-mail: quotation@sinoftm.com

Fill out the form below to leave a message, and get our latest special offer instantly

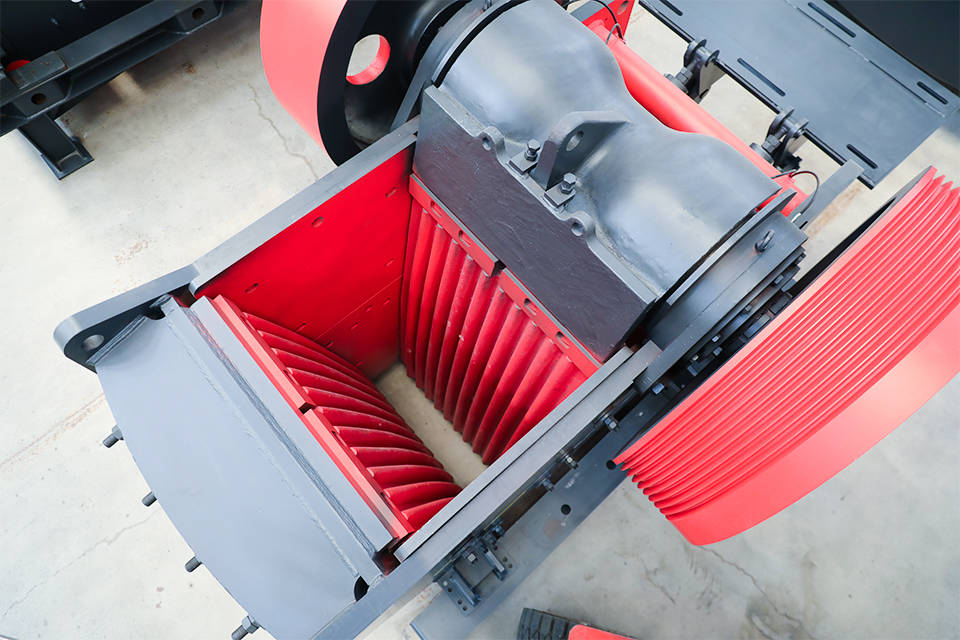

Jaw crusher is one kind of the best-selling crusher machine for stones and ores. Due to its high performance and competitive price, it is widely used for processing granite, limestone, quarry stones, gravel, basalt, aggregate, gold ore, iron ore, concrete, etc.

Jaw crusher is one kind of the best-selling crusher machine for stones and ores. Due to its high performance and competitive price, it is widely used for processing granite, limestone, quarry stones, gravel, basalt, aggregate, gold ore, iron ore, concrete, etc.

Our Jaw Crusher has been exported to over 160 countries, such as, Pakistan, Egypt, Indonesia, Malaysia, Ethiopia, Nigeria, South Africa, etc. Furthermore, we provide 100% factory price and maximum discount for you.

This cone crusher has been outstanding and has run smoothly for two years. It handles high-hardness granite efficiently with very little maintenance, which has greatly reduced our operating costs. This equipment has made a significant difference in boosting our business!"

"Jaw crusher has been updated for three times. There are different types and series of jaw crusher. The primary serie was researched and developed as the PE jaw crusher. In order to improve the quality of the jaw crusher, Henan Fote Heavy Mining Machinery which is a jaw crusher manufacturer in China actively introduced advanced technology from German to produce another serie of jaw crusher (HD) with a larger crushing ratio and higher output capacity. After researching from the market and the feedback from users, FTM machinery developed the European version jaw crusher(CJ). Comparing with the HD jaw crusher, the CJ has more advantages. It is assembled by the non-welded structure, so it’s easy to disassemble and transport. Besides, a motor is installed at the end of the machine. Therefore, the CJ jaw crusher has been popular among the majority of users. Besides, we also have many types of mobile crushers and crushers plants."

Our Jaw Crusher has been exported to over 160 countries, such as, Pakistan, Egypt, Indonesia, Malaysia, Ethiopia, Nigeria, South Africa, etc. Furthermore, we provide 100% factory price and maximum discount for you. Additionally, if you are new in this industry, we will provide professional suggestions and solutions for you.

High quality steel plate invoids the defects of casted steel making the whole frame more stable

Machines work more stably.

Discharging outlet dash adjusting easily and reliable. Convenient maintenance.

increase the feeding capability and capacity with big crushing ratio and even particle size.

In the process of breaking huge stones into small stones, the first crusher is usually the ' main ' crusher, and the longest and most solid crusher is the jaw crusher. When feeding the jaw crusher, the material is poured into the crushing chamber containing the jaw teeth from the top inlet. The jaw teeth top the material to the wall with great force and break it into smaller stones.

| Model | Feeding opening size(mm) | Max.Feeding size(mm) | Capacity (t/h) |

| HD72(57) | 460×720 | 425 | 50-120 |

| HD86(69) | 580×860 | 500 | 60-280 |

| HD98(751) | 680×980 | 630 | 110-410 |

| HD110(912) | 850×1100 | 750 | 230-550 |

| HD125 | 950×1250 | 900 | 280-750 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Maximum Feeding size(mm) | Capacity(t/h) |

| CJ96 | 480 | 105-390 |

| CJ106 | 560 | 150-500 |

| CJ120 | 700 | 175-610 |

| CJ125 | 760 | 270-831 |

| CJ150 | 960 | 340-880 |

| CJ160 | 960 | 430-1145 |

| CJ200 | 1200 | 630-1590 |

| CJ1511 | 850 | 380-1080 |

| CJ1513 | 1040 | 480-1160 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.